Material handling systems

Bulk material handling equipment is an important component in numerous industries. Companies in the mining, chemical processing, foundry, and food sectors count on it to deliver the ingredients and components needed for their processes. Because these systems are so important, companies need to partner with a bulk material handling company that has substantial expertise in designing and deploying them.

Our company is specializing in providing equipment solutions for your dry material handling problems.

Our material handling systems are mostly used in such industries as:

Ore mining industry

Cement production

Loading-unloading operations at sea and river ports

Oil refining industry

Other bulk materials handling

The main feature of these systems is their custom design. Each system, including its completeness and scope of supply is custom made for each specific Client.

In our systems, we are using top-quality components made by leading global manufacturers and we are trying to keep up to with time and use innovative technologies.

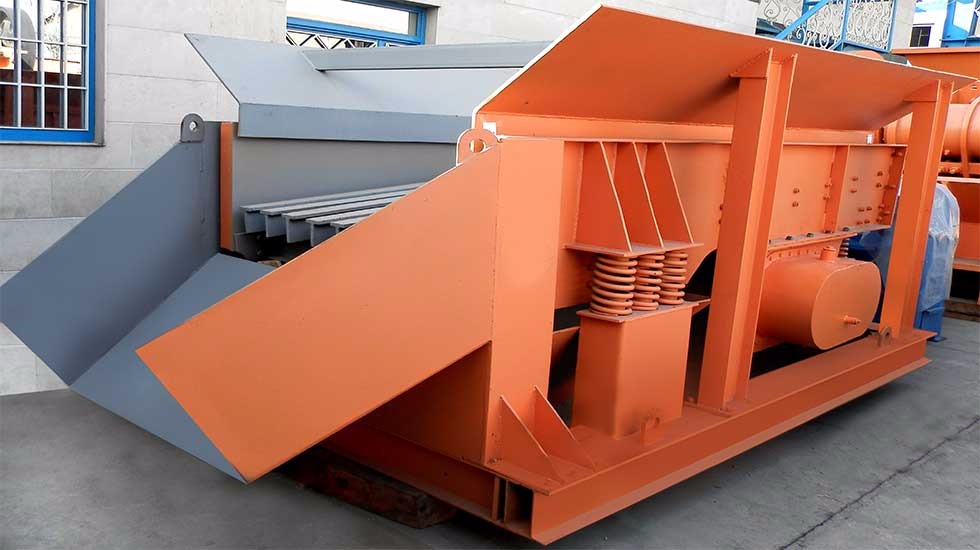

What kinds of equipment are used in a bulk material handling system?

Bulk material equipment and systems are manufactured according to the task that each unit is supposed to accomplish, but most systems incorporate the same general components and features. A full system generally features:

- Loading machines. The system always starts somewhere, in this case it is the point where materials can be discharged into the system. This portion of the system can take many forms depending on circumstances. Normally, the initial point is the loading hopper over the first conveyor of the system.

- A conveying system. There are no restrictions in this part of the system: we can use any conveyors (screw, pneumatic, etc.). We can also combine several types of conveyors in one system.

- Reclaimer machines. Stacker/reclaimer machines are used to stack and store materials in stockpiles and stockyards and to reclaim materials when needed.

In order to utilize bulk materials efficiently, batching equipment is used to accurately dispense bulk materials.

- Loadout station. Once the bulk materials have been processed, the system needs a method for offloading the final product for packaging or shipment.

Despite the fact that almost all systems include all types of the above equipment, we can use different options for the layout of this equipment, as well as include additional components. All equipment is selected depending on your processing material.